IMET

GBS 130

Manual bandsaw for cuts from 0° to 60° left. Suitable for small carpentry and for installers.

Frontal vice, locking lever on different angle, jaw height 65 mm. Practical locking of the sawframe to easily transport the machine at work sites. Band guides with lateral bearings. Start button inside the ergonomic handle . Supplied with bi-metal blade. Floor stand optional. High performance 220 volt mono-phase motor with continuous regulation of the blade speed, double protection against overheating and overload.

Cutting Capacity: Rounds till 130 mm., square till 130 mm. and rectangular till 130×125 mm.

Cutting Capacities and Technical Data HERE

GBS 218 GH – Currently OUT OF STOCK – More Coming Soon

Manual or gravity lowered band saw for cuts from 0° to 60° left. Ideal for small carpentry cuts. Suitable for small productions section bars, tubes, and solids up to 60° left.

Steel sawframe with tubular steel section. Adjustable stops at 0°, 45° and 60° left with lever for locking on different angles. Graduated plate for identifying different angles. Blade guides with hard metal pads. Safe push button start on the handle. Warning light for correct functioning. Low voltage coil. Floor stand with opening in the back for storage, a removable coolant tank, and electro-pump included.

Cast iron sawframe inclined to 42° so the blade will not be strained excessively. The blade tension is 1500kg/cm², which allows for more accurate and faster cuts. The AUTOCUT GH version is for independent cutting, with three-position selector:

-Manual Cut

-Rapid Approach to Material

-Automatic cut with autonomous lowering and stopping microswitch at the end of the cut.

Cutting Capacities and Technical Data HERE

GBS 218 GH

GBS 218 GH Blade+Arch

BS 300/60 GH

Bandsaw for cuts of 0° to 60° left with material of medium hardness and for medium productions.

Equipped with a blade guard for rapid and easy replacement of the blade. Frontal vice with fast clamping (jaw height 130mm) and adjustable length stop. Easy stops at 0°, 45°, and a graduated plate to identify different angles. Blade guides with hard metal pads, additional bearing for balde alignment. Safe starter with the button on the handle with a warning light for correct operation. Floor stand, coolant tank, and electro pump included.

Our AUTOCUT GH version is equipped with a main switch with a padlock closure. A minimum tension coil, for thermic & magnetic protection and motor absorption ammeter.

3 position selector for:

-Manual cut

-Manual cut with descent brake

-Automatic cut with autonomous lowering (which is adjustable) and stopping microswitch at the end of the cut.

Cutting Capacities and Technical Data HERE

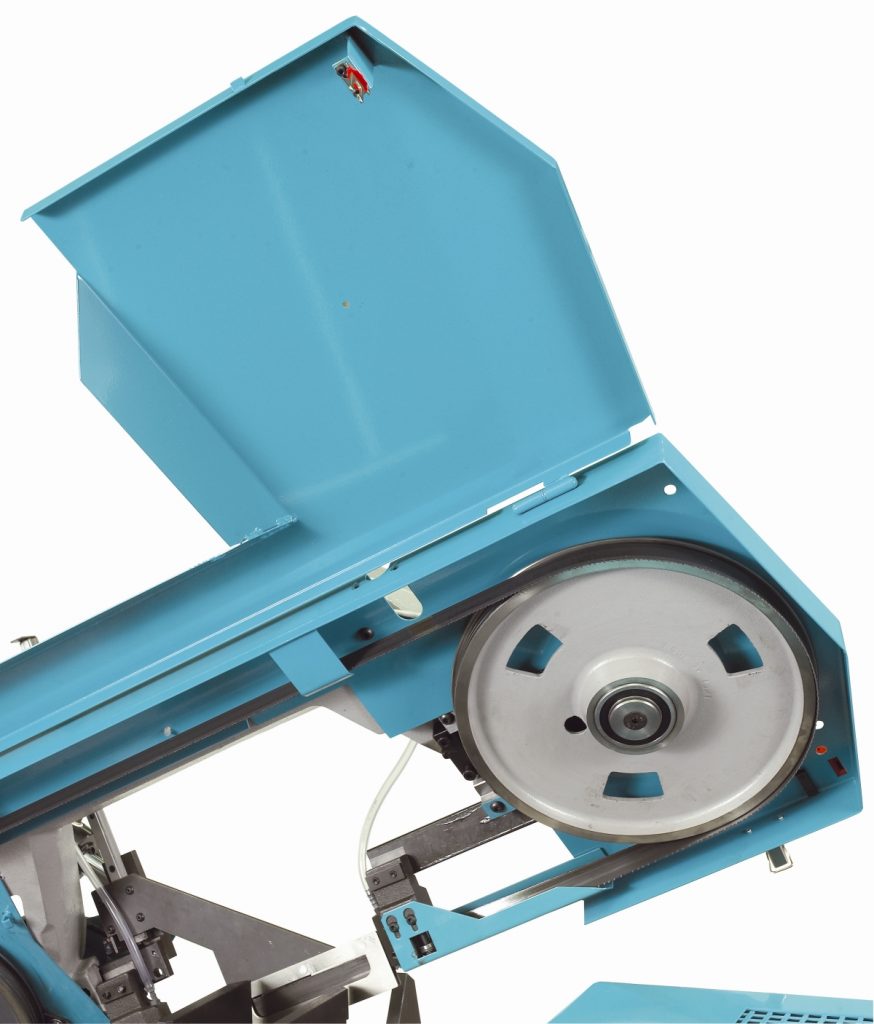

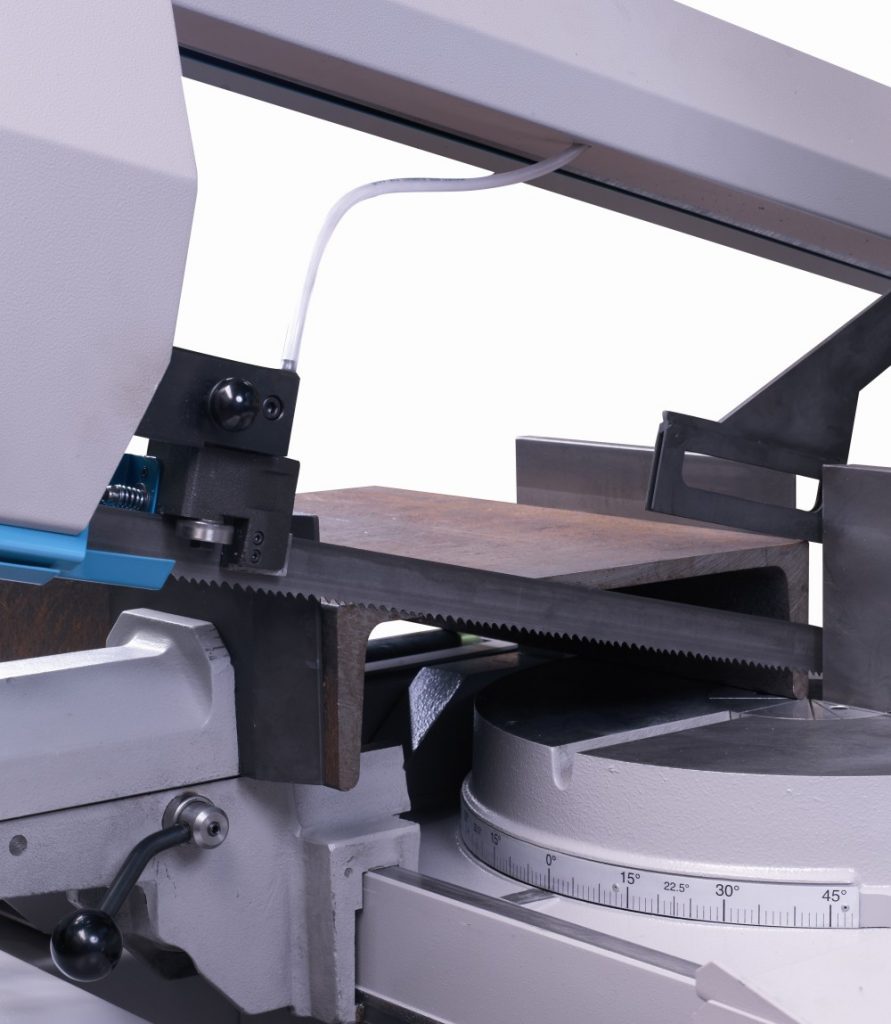

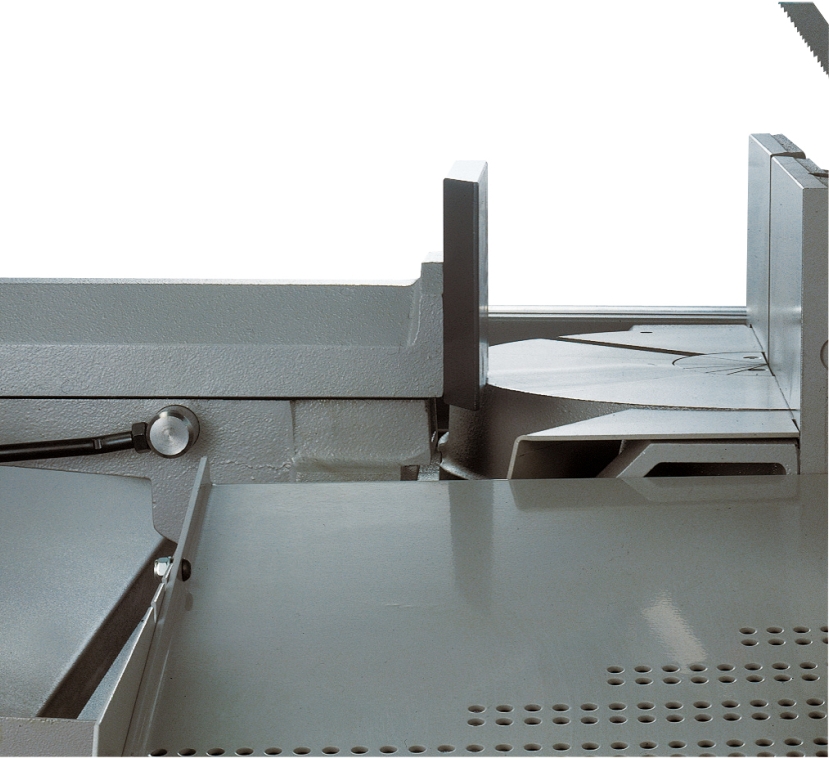

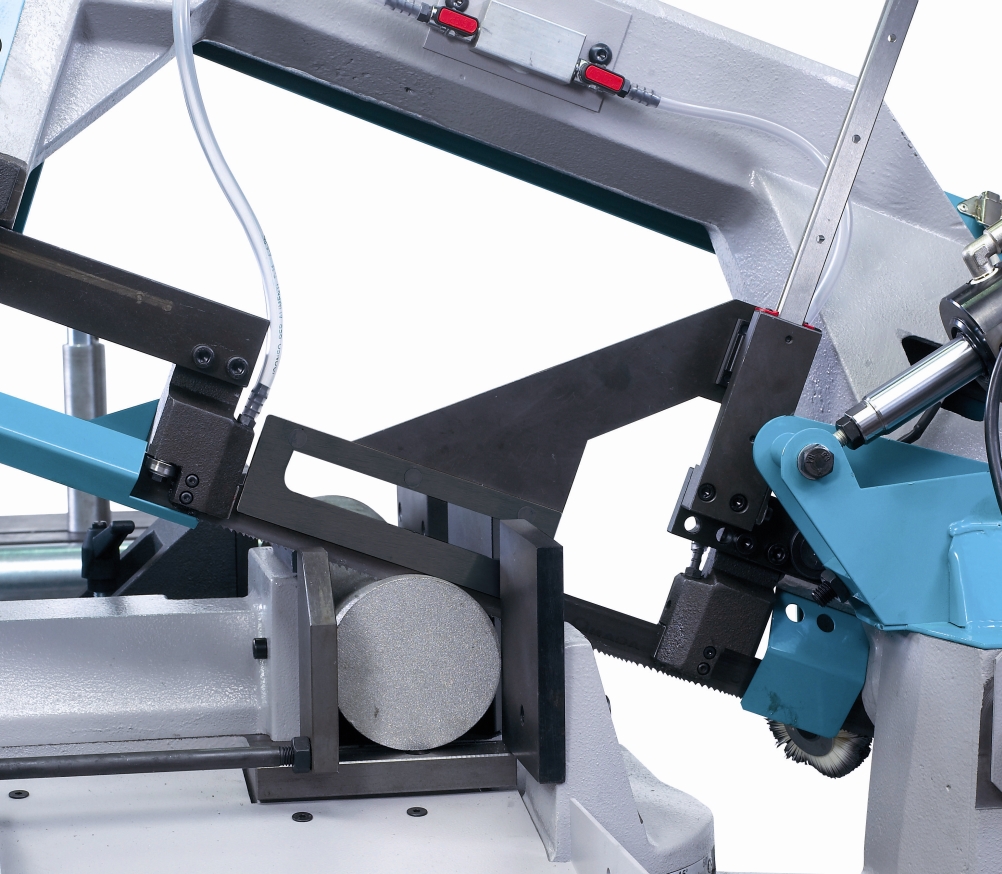

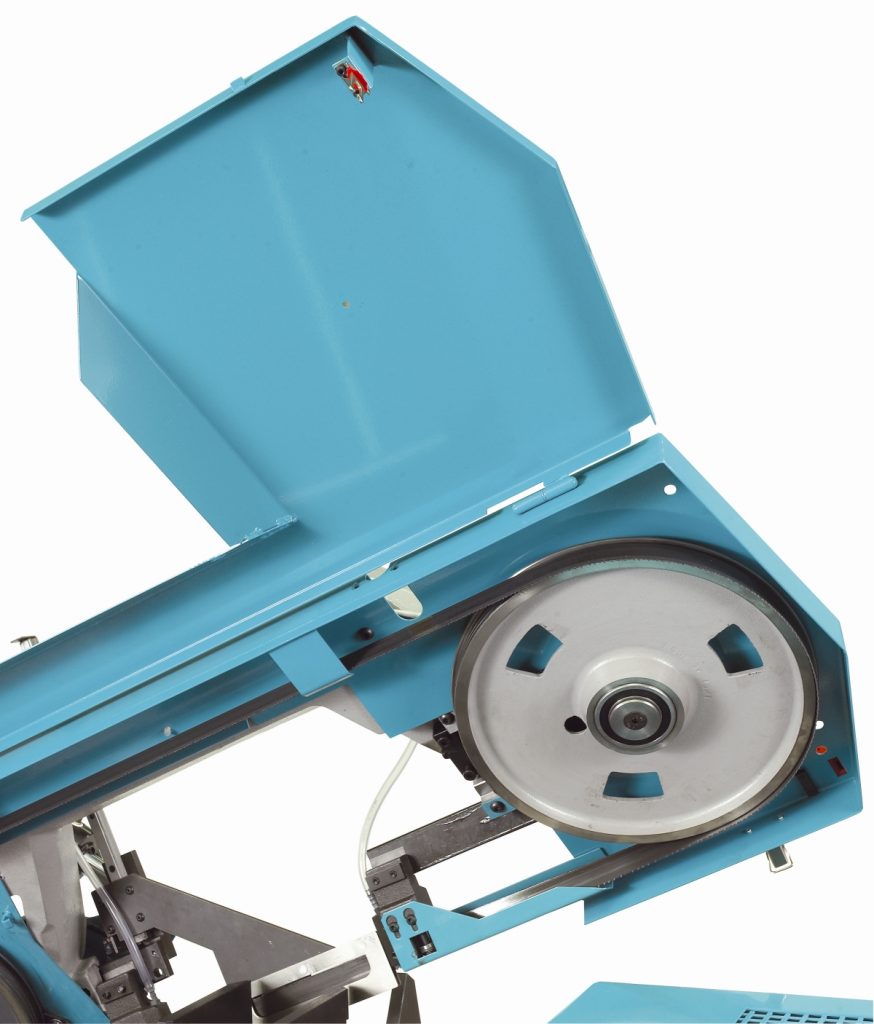

BS 400 SHI

Semiautomatic hydraulic bandsaw, for medium and heavy steelwork, mitre cutting up to 60° left and 45° right.

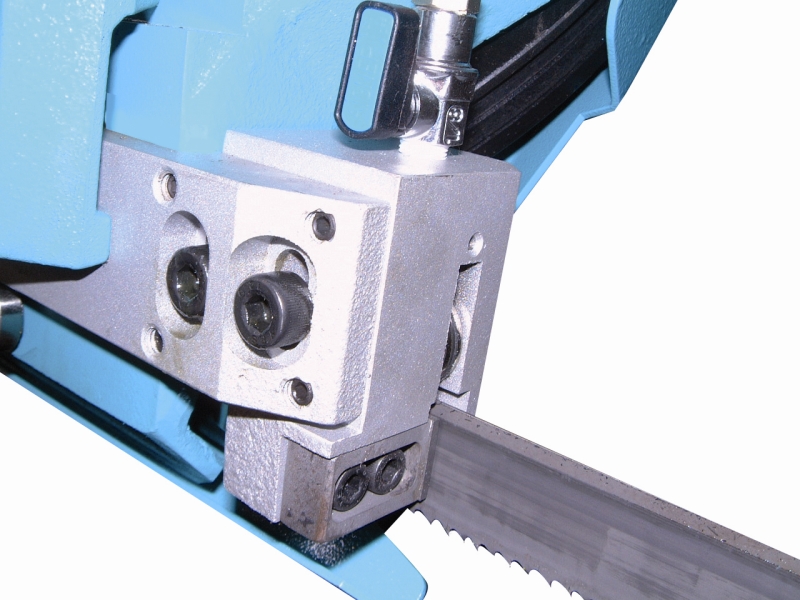

Equipped with a hydraulic vice with adjustable guides, free to move alongside the worktable, quick motion and clamping. Easy stops at 0°, 45°, 60° left and 45° right. Adjustment of the blade tension from the front side of the saw-frame, checked by an end-stroke. Blade guides with hard metal pads, additional bearing for blade alignment. Steel saw frame with tubular section, pulley – 360 mm diameter. Position sensor that allows the saw frame to quickly lower toward the material and automatically detect the starting point of the cut. Connection element for the loading table equipped with a roller, 450 mm wide. Slide on the unloading side which can be transformed into a connection for an unloading table. Adjustable bar stop, blade-cleaning brush, and a bi-metal blade. Main switch with minimum tension coil, emergency button, thermic and magnetic motor protection. Motor absorption device. Option to connect a pedal to start the cutting cycle. Floor stand with storage room inside. Removable chip collector, coolant tank and electro pump. Wide working space (460mm diameter) with rotating table integral with the saw frame to avoid incisions on the table, rotation on a thrust ring with pre-loaded thrust bearing.

Cutting Capacities and Technical Data HERE

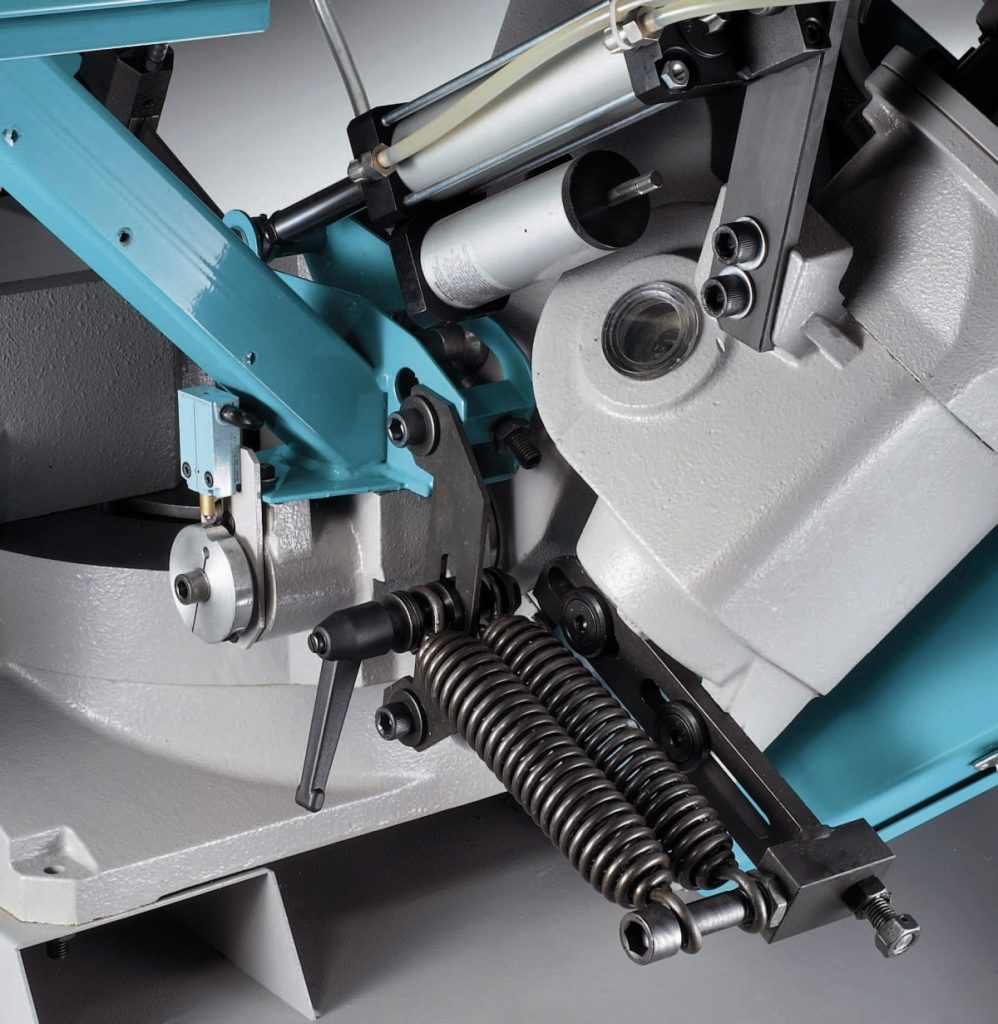

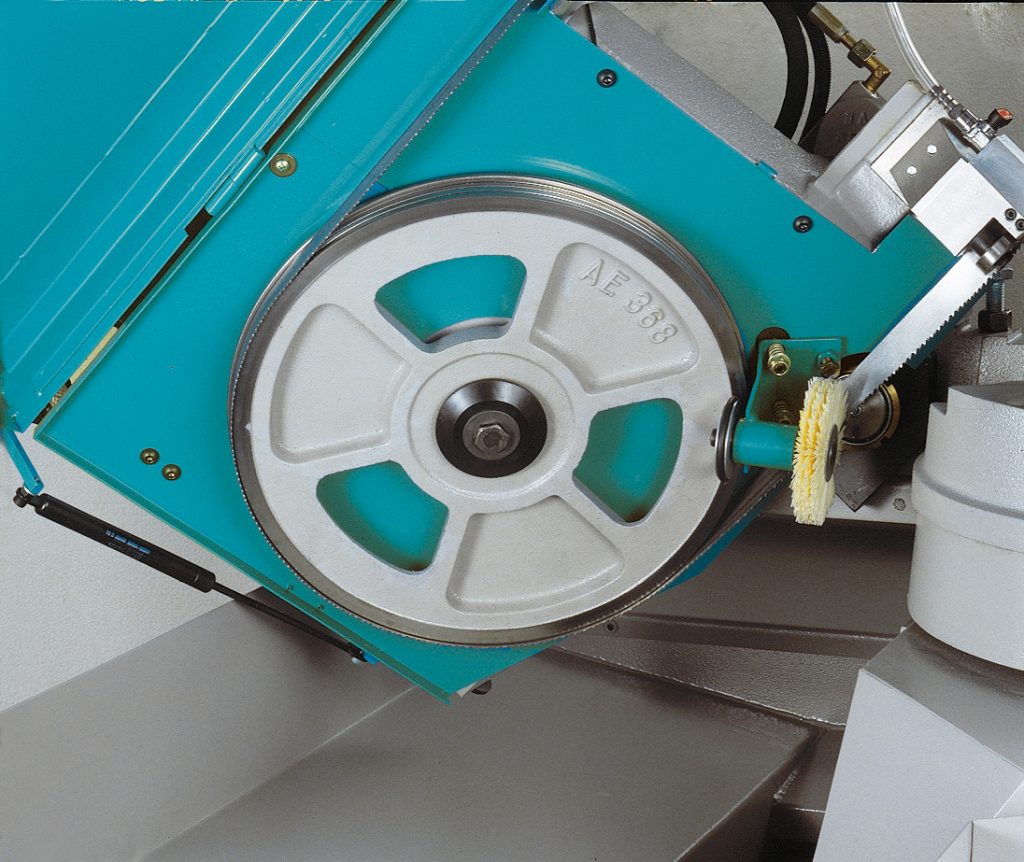

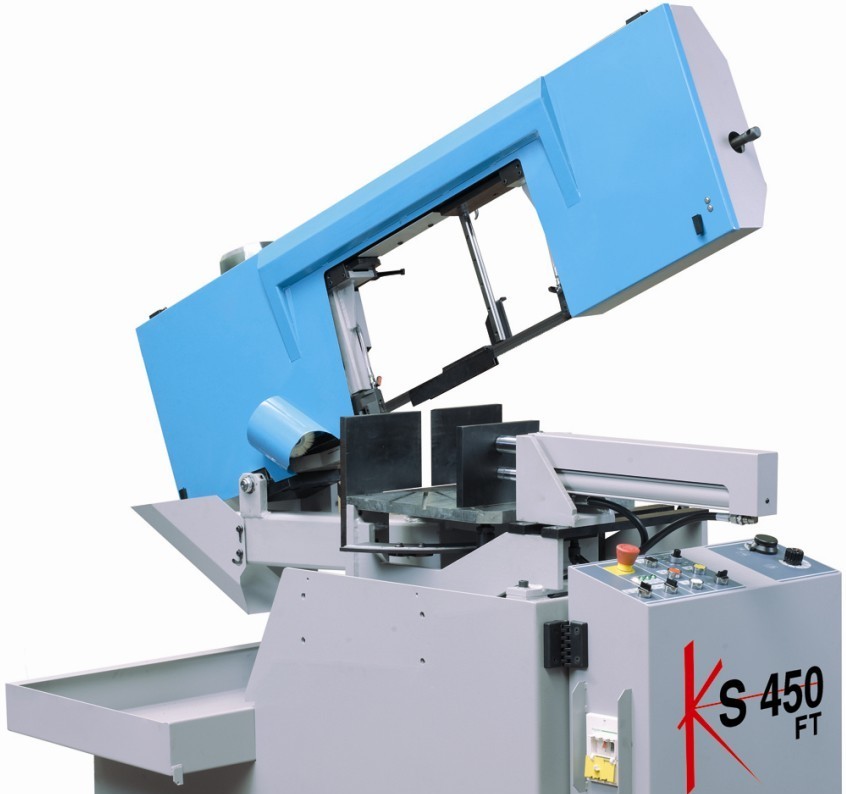

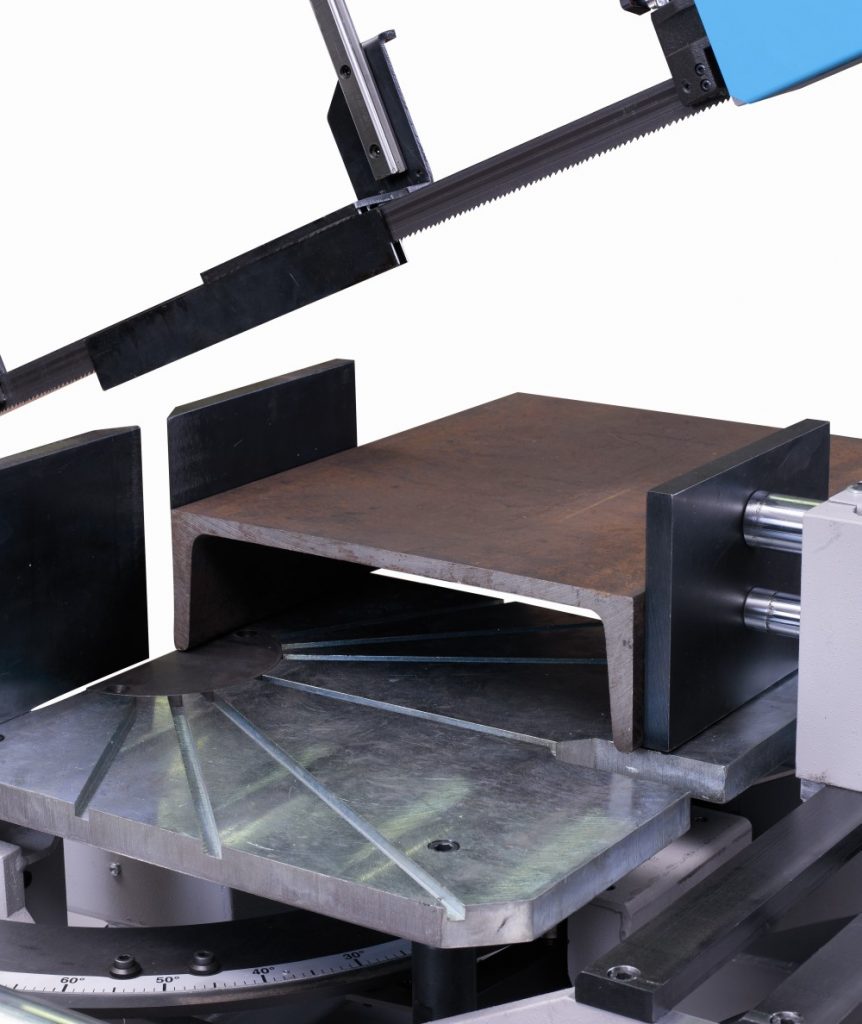

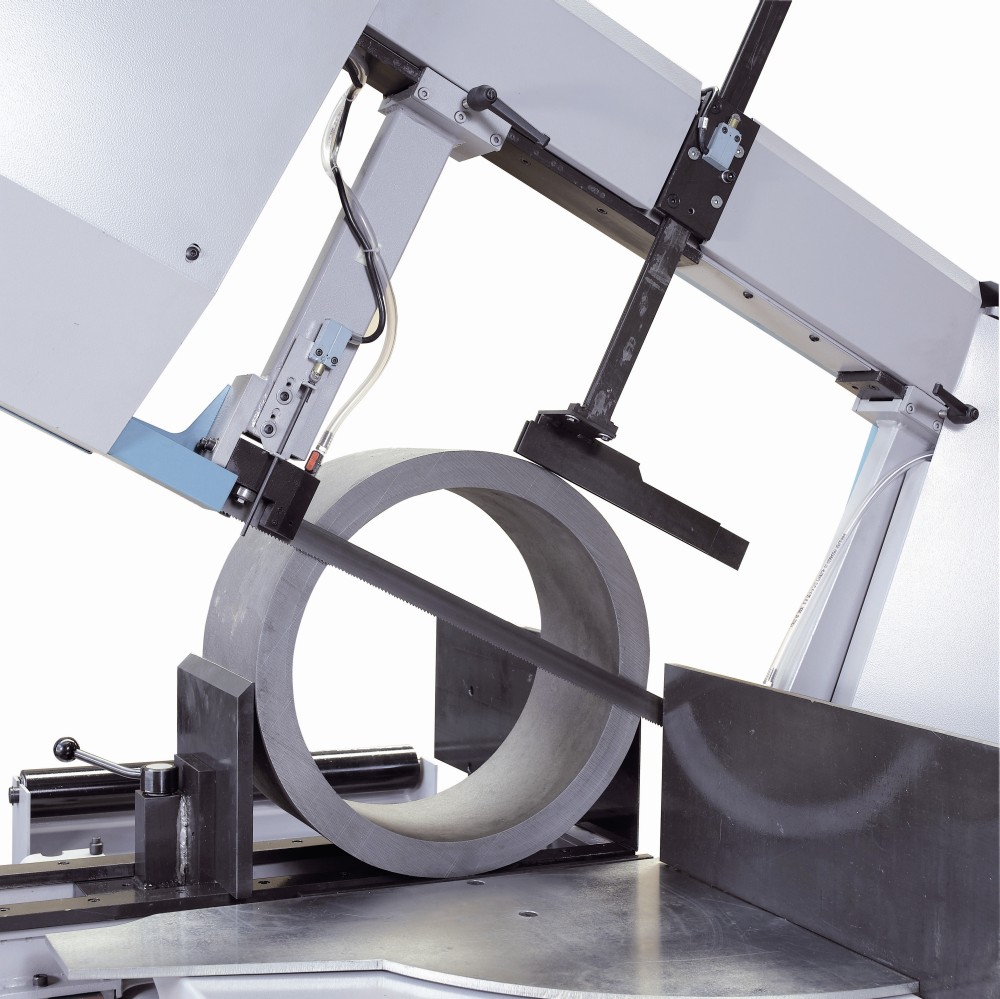

KS 450 FT

Suitable to cut structural steel, pipe, profile, and beams. Mitre cutting up to 60° left and right, easy stops at 0° and 45° left and right.

Strong steel sawframe with tubular section (pulleys diameter 360mm). Hard metal pads inside the blade guides. Ability to slide the frontal vice along the work table. Wide working space to support the material. Position sensor that allows the sawframe to lower quickly toward the material and automatically detect the start and end cut point. Adjustment of the lowering power and speed. Frontal console with 3-way selector to choose different working modes: the return of the sawframe with steady blade, or end at the cutting cycle without the return of the sawframe. Control lights on the control panel to check blade tension, blade cover, motor thermic over loading, and power supply. Easily arch rotation due to preloaded bearings setting. Floor stand with removable chip collector. Coolant tank with electropump. Hydraulic unit with oil. Bladecleaning brush for the bi-metal blade.

Cutting Capacities and Technical Data HERE

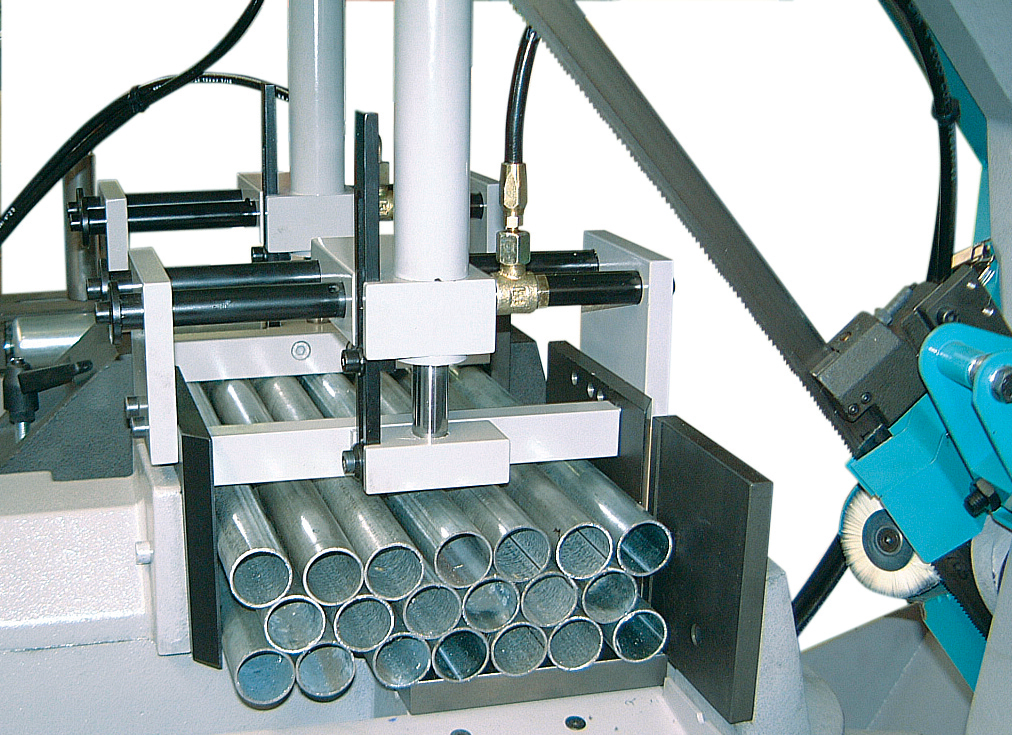

Cubo 300 NC Flat

CNC automatic bandsaw that is hydraulically driven. Mitre cutting from 0° to 45° left in an automatic cycle and from 0° to 60° left in semiautomatic cycle. CUBO 300-NC-FLAT is an Industry 4.0 tool and has the possibility to be used remotely.

Easy stops at 0°, graduated plate to identify different angles. Hydraulic vices (Jaw height 130 mm). High blade tension (1700 kg/cm²) to increase cutting accuracy and reduce cutting time. Easy settting from the front of the sawframe with a microswitch check. Blade guides with hard metal pads. Blade guard which allows an easy and quick replacement of the blade. Machine can be set up to 99 programs, with the ability to repeat them more than once. CNC programming of all operations; automatically calculating the blade thickness. Machine status shown on display, including the blade speed, piece counter, and working anomalies. Set the cutting lengths (from 4 to 9999 mm) by means of keyboard, with automatic repetition of the feeder strokes (Max single stroke 515 mm). Connection for a loading table with 2 vertical rollers, unloading slide. Connection for unloading table for cutting pieces. Main switch with minimal tension coil, emergency button, thermic and magnetic motor protection. Removable chip collector tank, coolant tank with electro-pump, hydraulic unit with oil. Bladecleaning brush, bi-metal blade.

Cutting Capacities and Technical Data HERE